Range

Control Units

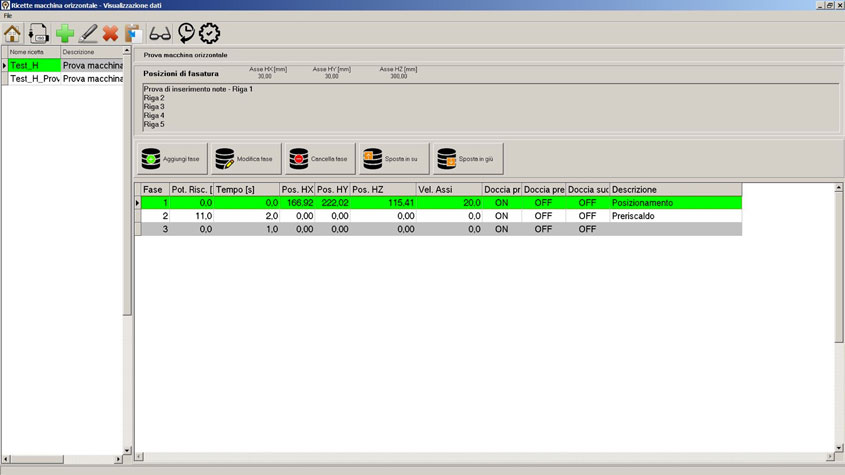

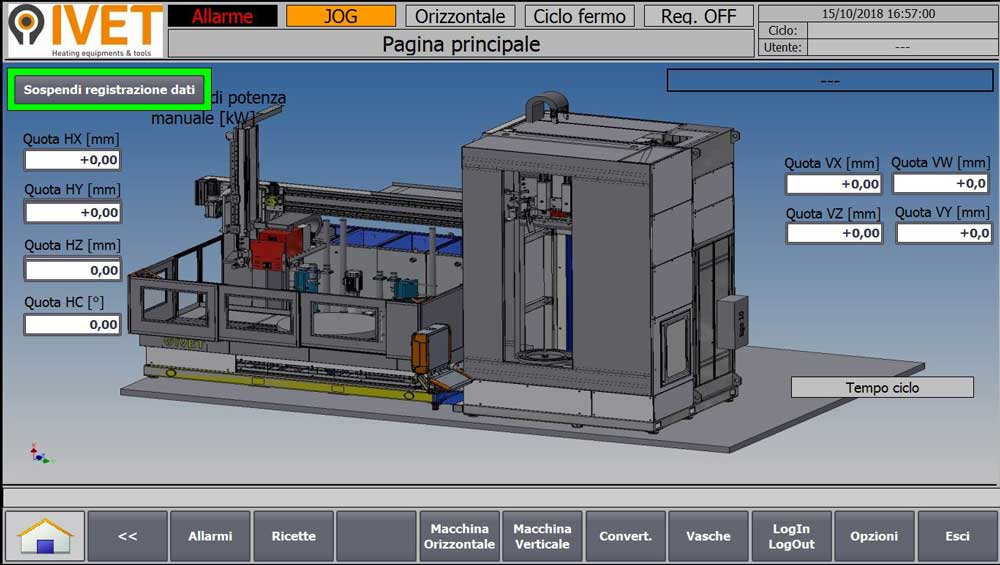

Command and control systems for machines – Software man/machine (HMI)

Process control systems – PLC software

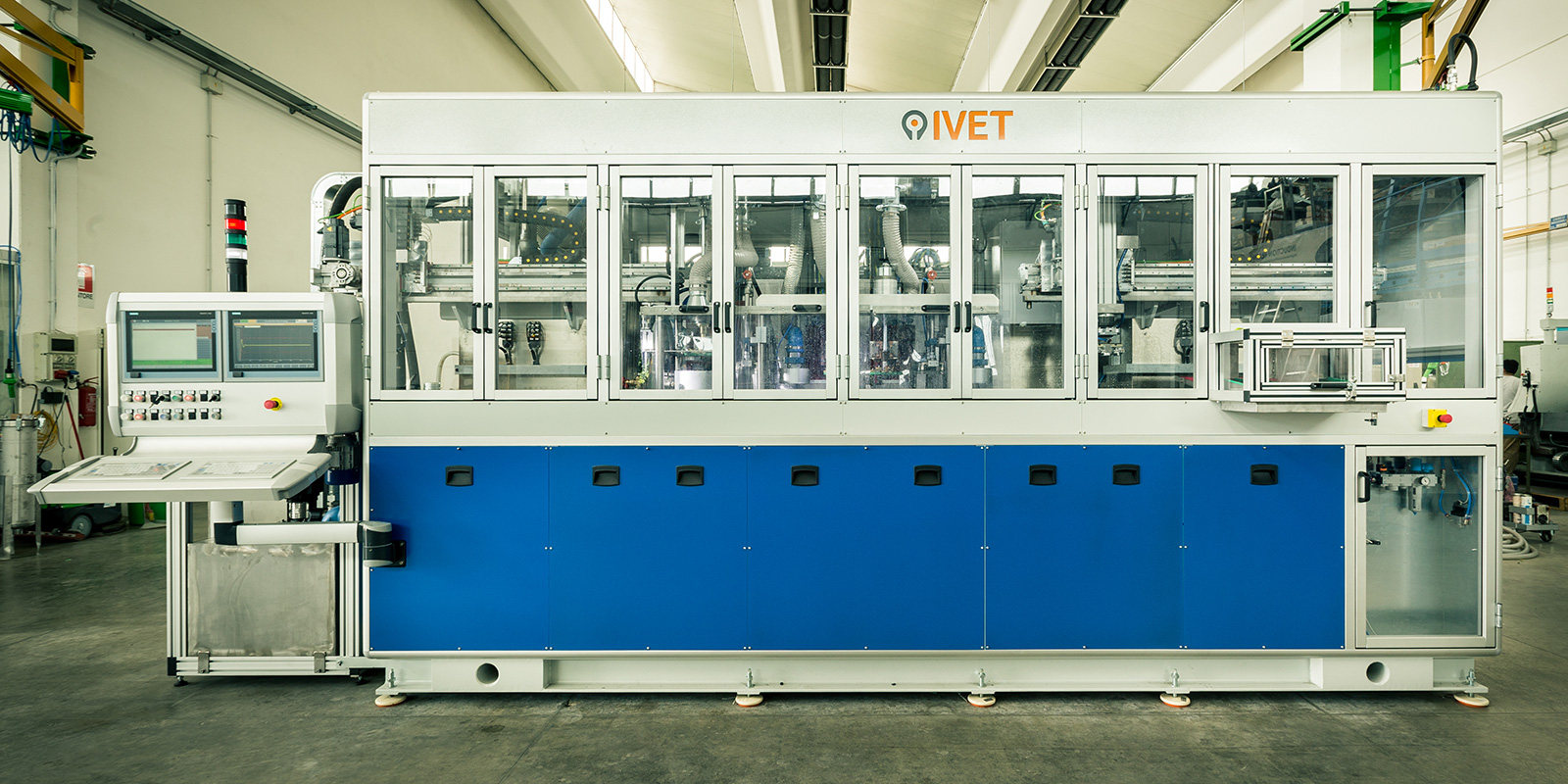

We have specific software dept. (SD) for design and development of complete systems for command and control machines and process. Particularly, SD design “user friendly” interface man/machine (HMI) software, useful for no expert operator and always in safety condition.

Machine Control and Command Systems

They consist of:

- PLC + Operator Panel, for simple applications.

- PLC + axes control unit + industrial PC, for more complicate and evolved machines.

- PLC + CNC, for machine with particular functions or with interpolation multi axes machine.

Software

- Logical programmable (PLC) software always with comments.

- Man/machine software (HMI) with industrial PC, developed with specific software, work in Windows OS and design on reference of machine type.

- Application under CNC, use of ISO language.

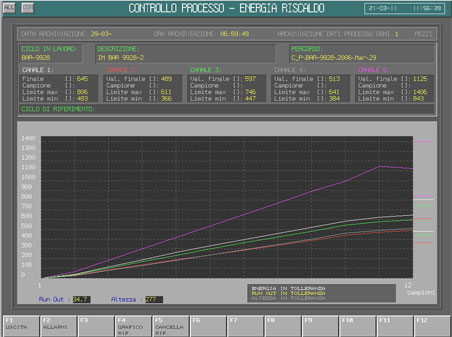

Process Management

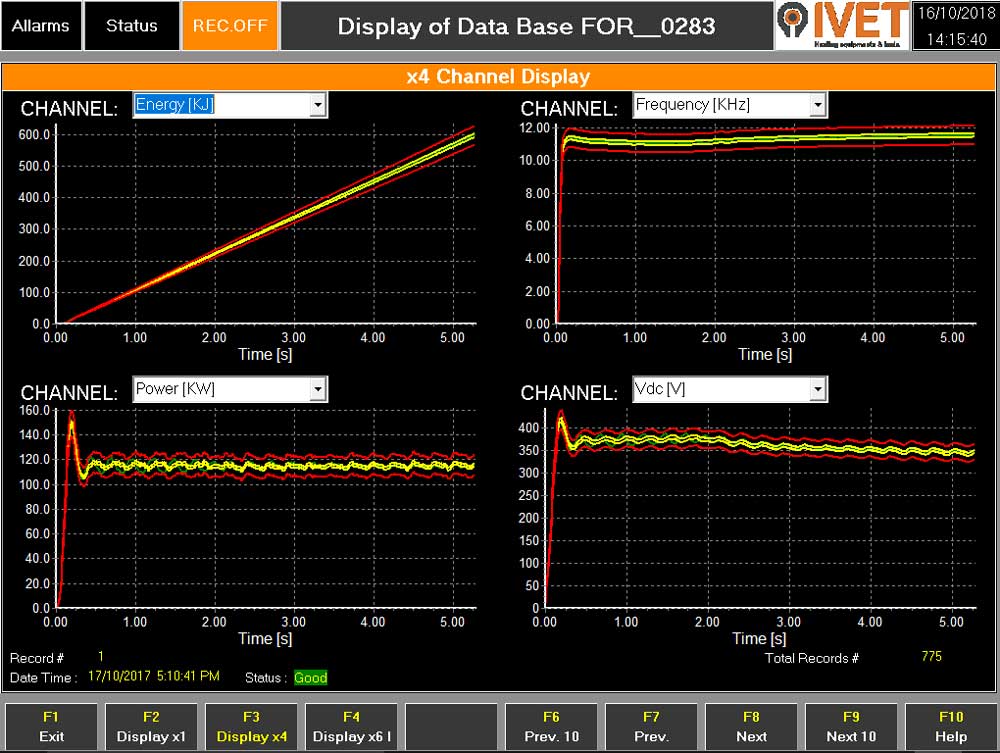

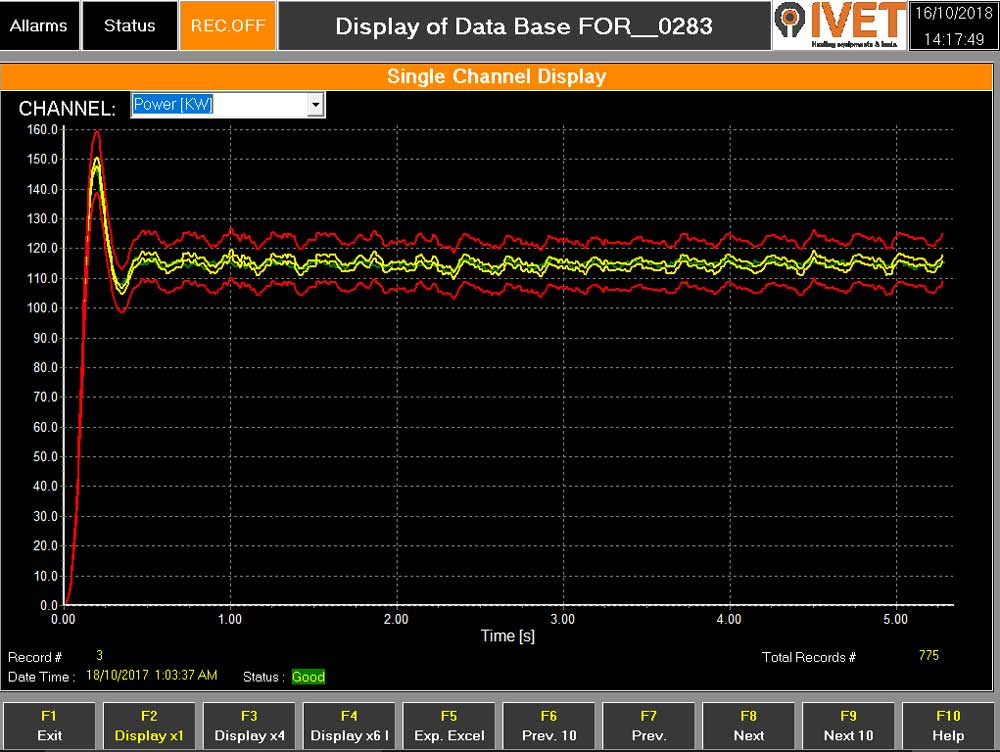

Differentiated level systems, based on the number of control channels:

- BASIC = heating energy control and quenching shower flow control.

- MIDDLE = heating energy control, oscillating frequency, quenching shower flow, quenchant temperature.

- EVOLVED = heating energy control, voltage, current, frequency, quenching shower flow, quenchant temperature. Inductor collision detect.

- CUSTOM = the number of controls (channels), is selected on reference to the safety level of the process and product.

Production traceability

Hardware and software, specialized or integrated in the man/machine interface, for the collection and storage of production history.