Machines

Special Machinery

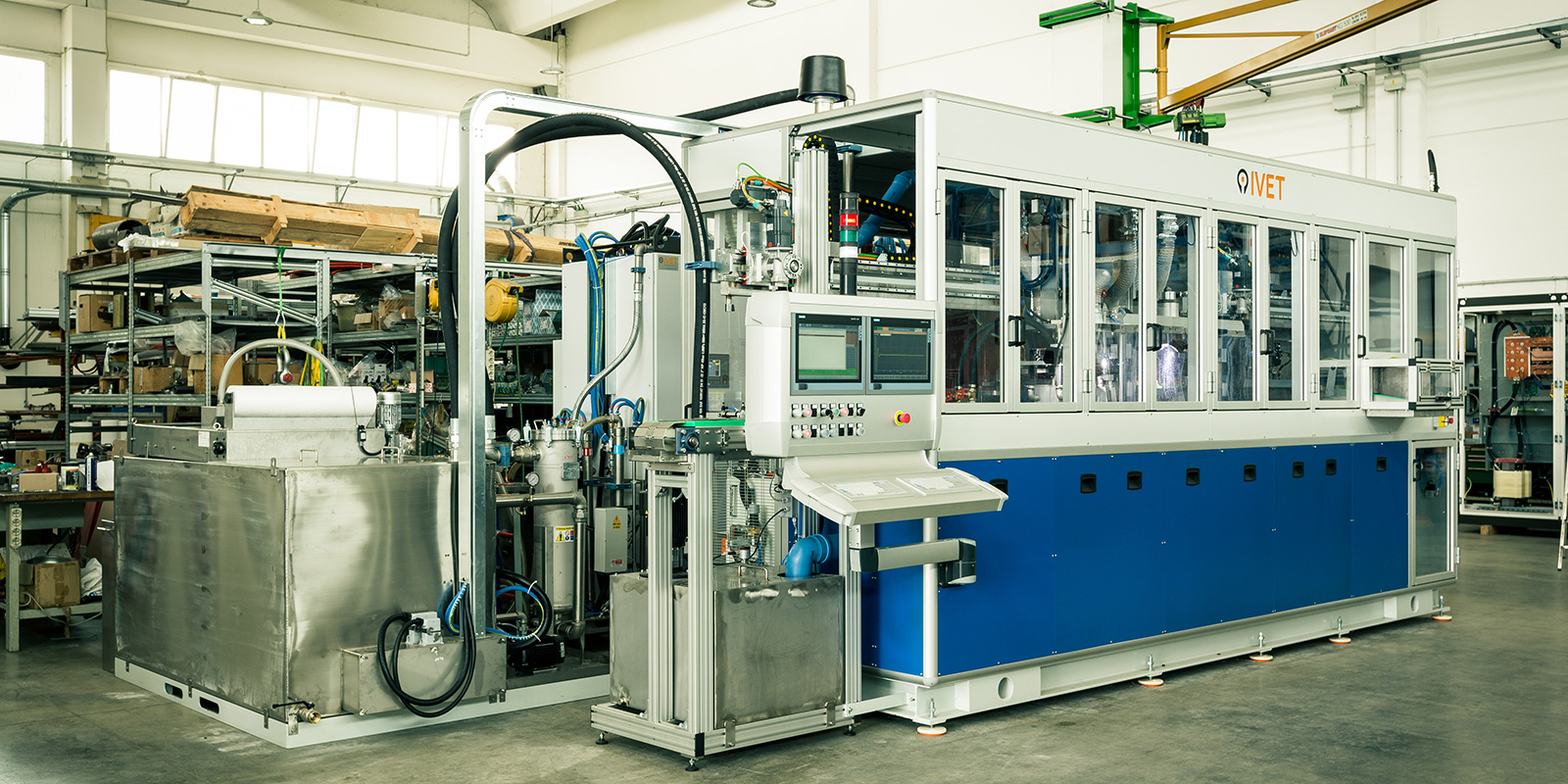

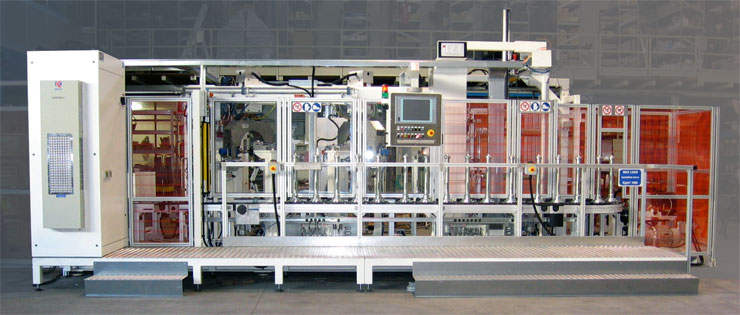

Global vision of the complete technological process.

Development of multiple processes, integrated in induction machines.

Ivet is able to deal with complex problems which require specific skills in different fields.

Our organization allows us to integrate processes and auxiliary functions directly into the induction heating machine, without the need for extra machinery.

For our customers, this results in cost reduction and a single point of contact over the design phase, start-up and after-sales service.

Automatic system for welding the limit switch bush on the shock absorber stem and verification test.

Automatic system, equipped with a transport system by means of pallet recirculation and multiple series processing stations, which are dedicated to:

- Station 1 = rod measurement, verification of bushing presence and orientation.

- Station 2 = pre heating by induction on welding zone.

- Station 3 = first couple of welding spot and automatic “coloring” system of welding.

- Station 4 = computer visual check of first welding spot.

- Station 5 = second couple of welding spot and automatic “coloring” system of welding.

- Station 6 = computer visual check of second welding spot.

- Station 7 = test of “sliding bushing” at 100%, with double control with force applied and bushing position. Automatic marker system. Automatic system of force applied verification by a “load cell” with integrated certification.

- Station 8 = automatic unloading system.

- Production = over 500 pieces/hour.

- Rod lenght = up to 500 mm.

- Rod diameter = up to 28 mm.

Ivet has a specific department for the programming and developing of full systems for machine and process control. In particular, we develop user friendly Human-Machine Interface (HMI) softwares, which can be safely used by non-expert personnel.