Machines

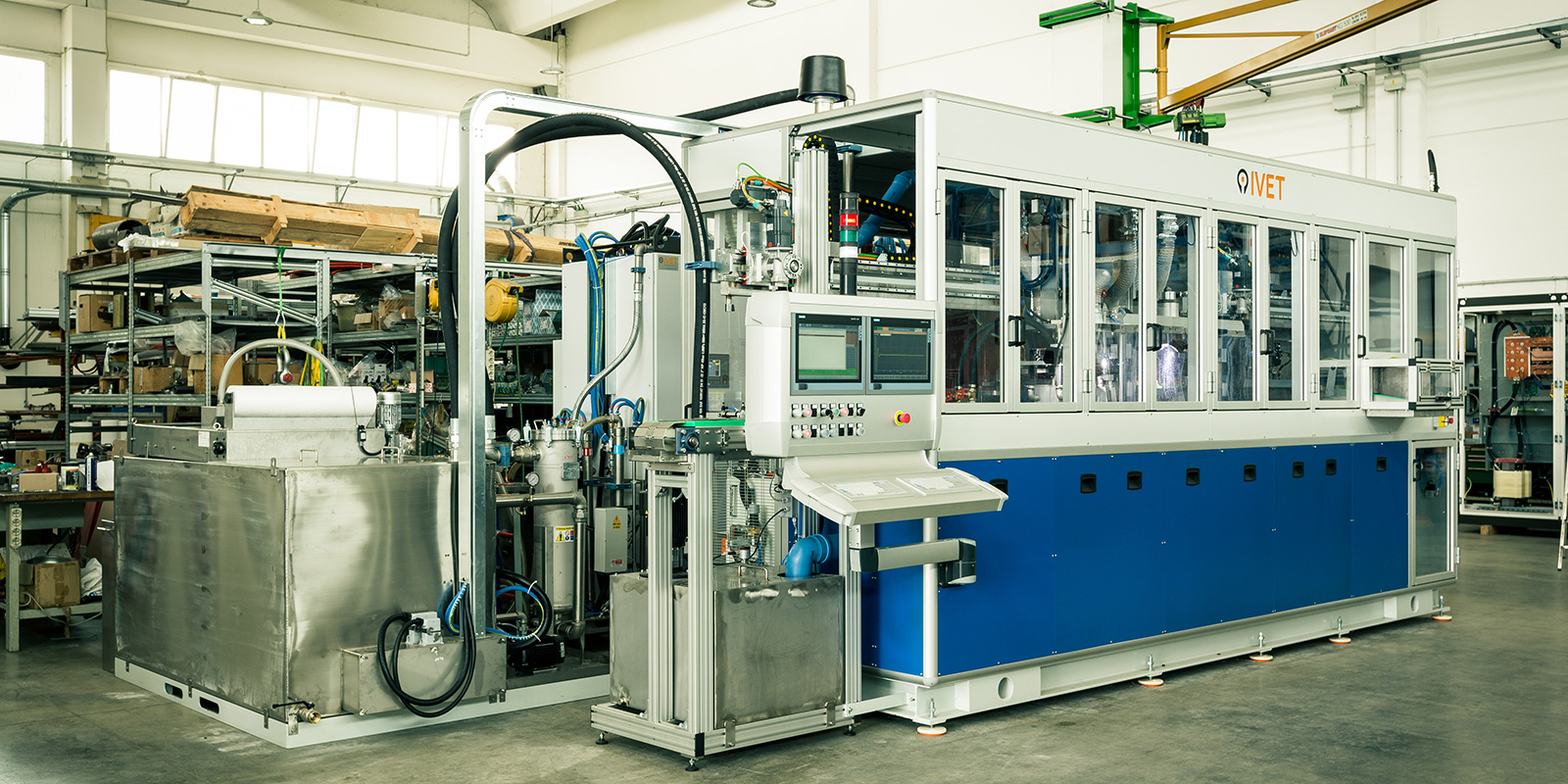

Multiple axes heat treating machine series MTM

MTM series hardening machines have multiple controlled axes and are recommended for treatment of large pieces such as:

- Plate wheel and Pulleys

- Large bearings

- Rails and guide, which require “horizontal scanner” hardening

- Sprockets, also with helicoidal teeth and other similar parts

HMI interface was designed directly by Ivet, specifically for this machine. It is very easy and intuitive, ensuring fast and safe programming, even by non-expert personnel.

The machine can also be supplied with CNC (ISO language program).

MTM 3000 4ac 1P

Due to its versatility, this machine is very suitable for heat treatment sub supplier.

- Four controlled axes: circular + vertical + horizontal + transverse.

- Three jaw chuck and full adjustable inductor position.

- Pieces diameter: up to 3000 mm.

- Piece height: up to 900 mm.

- Horizontal axis length: 2500 mm.

- Corsa asse verticale: 1100 mm.

- Vertical axis length: 1100 mm.

- Self-centering three jaw chuck.

- Automatic and self-adjustment airgap between piece and inductor.

- Convertible in a e position turn table machine.

- Special “recovery cycle” for tooth by tooth process.

- Recommended power: 150 ÷ 200 kW.

- PLC control system + industrial PC.

- Easy HMI Software.

- Webcam to monitor hardening area.