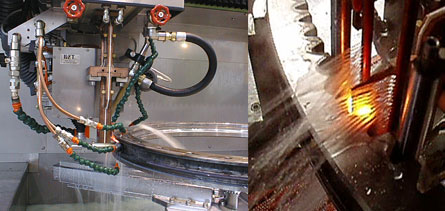

Case studies

Automatic machine for hardening of slewing bearing and tooth gear

Technical requirements

- Hardening of internal/external raceway.

- Hardening of double raceway.

- Hardening of internal/external tooth gear.

- No load/unload waste lost.

- Low adaptive operation to pass from slewing bearing to tooth gear.

- Low setup time machine.

- Automatic inductor cleaning procedure.

- Hardening control process parameters.

Product

- Slewing bearing with diameter from 300 to 1500 mm.

- Raceway diameter up to 40 mm.

- Tooth height up to 150 mm.

Solution

MTR1500_4ac_2P machine description:

- Double hardening station, each with automatic self centring chuck.

- Automatic self centring inductor-raceway.

- Automatic tuning for constant air gap inductor-raceway.

- Automatic self centring inductor-tooth.

- Automatic cycle for double hardening raceway.

- Automatic “recovery” cycle for tooth by tooth hardening.

- Circular scanner hardening process for raceway.

- Vertical scanner hardening process for tooth.

- Hardening power unit 150 kW – 10 – 15 kHz.

- Station for automatic cleaning of inductor.

- No lost time for load/unload operation.

- Complete control parameter integrated for both hardening process.

- Setup up time: 15 minutes.